What are Car Suspension Parts?

Car suspension parts are essential components that connect a vehicle to its wheels, ensuring a smooth and stable ride. These parts work together to absorb shocks from the road, maintain tire contact, and provide optimal handling. Understanding these components is crucial for vehicle maintenance and performance.

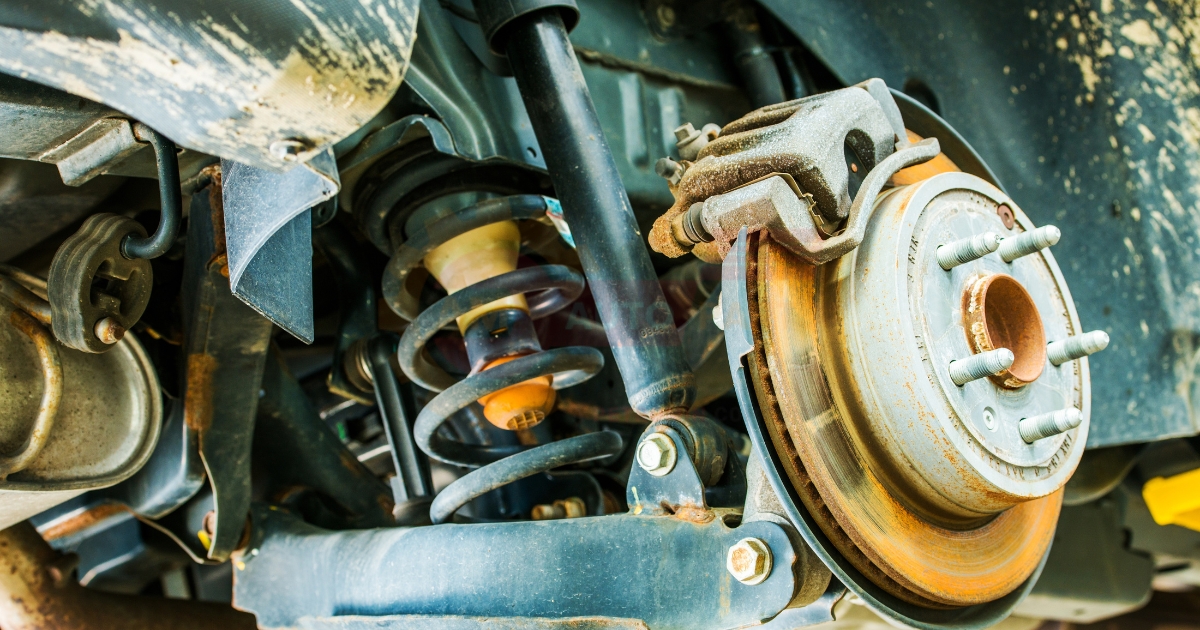

Key Components of Car Suspension

- Springs : Springs are fundamental in absorbing shocks and maintaining the vehicle’s height. They come in various types, including coil springs, leaf springs, and torsion bars.

- Shock Absorbers : These dampen the oscillations of the springs, providing a smoother ride by controlling the rebound and compression of the springs.

- Anti-roll Bars : Also known as sway bars, these components reduce body roll during cornering, enhancing vehicle stability.

- Ball Joints : These spherical bearings connect the control arms to the steering knuckles, allowing for smooth movement and steering.

- Control Arms : These link the wheel hub to the vehicle frame, enabling up and down movement while maintaining wheel alignment.

Types of Car Suspension Systems

Dependent Suspension System

A dependent suspension system connects the wheels on the same axle, causing them to move together. This system is commonly found in heavy-duty vehicles due to its robustness.

- Advantages : Simple design, cost-effective, and durable.

- Disadvantages : Less comfortable ride, limited independent wheel movement.

Independent Suspension System

In an independent suspension system, each wheel moves independently, providing a smoother ride and better handling. This system is prevalent in modern passenger cars.

- Advantages : Improved ride comfort, better handling, and enhanced traction.

- Disadvantages : More complex and expensive to maintain.

Semi-Independent Suspension Systems

Semi-independent systems offer a middle ground, allowing some degree of independent wheel movement while maintaining a connection between the wheels.

- Advantages : Balance between comfort and cost, suitable for various vehicle types.

- Disadvantages : Compromised performance compared to fully independent systems.

Functions of Suspension Parts in Vehicles

Improving Ride Comfort

Suspension parts play a crucial role in absorbing road shocks and vibrations, ensuring a comfortable ride for passengers.

- Springs : Absorb vertical forces from the road.

- Shock Absorbers : Control the rebound and compression of springs.

Enhancing Vehicle Stability

Stability is vital for safe driving, especially during cornering and braking. Suspension components work together to maintain vehicle balance.

- Anti-roll Bars : Reduce body roll during turns.

- Control Arms : Maintain wheel alignment and stability.

Maintaining Proper Wheel Alignment

Proper wheel alignment ensures even tire wear and optimal handling. Suspension parts like control arms and ball joints are essential for maintaining alignment.

- Ball Joints : Allow smooth steering and wheel movement.

- Control Arms : Keep wheels aligned with the vehicle frame.

Manufacturing Methods for Suspension Components

Metal Casting

Metal casting involves pouring molten metal into a mold to create suspension parts. This method is suitable for producing complex shapes.

- Advantages : Cost-effective for large production runs, versatile.

- Disadvantages : Potential for defects, limited material options.

Forging

Forging uses compressive forces to shape metal, resulting in strong and durable suspension parts.

- Advantages : High strength, excellent fatigue resistance.

- Disadvantages : Higher cost, limited to simpler shapes.

CNC Machining

CNC machining uses computer-controlled tools to precisely cut and shape suspension components.

- Advantages : High precision, suitable for complex designs.

- Disadvantages : Expensive, slower production rate.

Injection Molding

Injection molding is used for producing plastic suspension parts by injecting molten plastic into a mold.

- Advantages : Cost-effective for large volumes, high repeatability.

- Disadvantages : Limited to plastic materials, high initial setup cost.

Importance of Quality Suspension Parts

Impact on Vehicle Performance

High-quality suspension parts are crucial for optimal vehicle performance, affecting handling, ride comfort, and fuel efficiency.

- Enhanced Handling : Better control and stability.

- Improved Comfort : Smoother ride over various terrains.

Safety Considerations

Quality suspension components are vital for vehicle safety, reducing the risk of accidents caused by poor handling or component failure.

- Reduced Accident Risk : Better control and stability.

- Enhanced Braking : Improved stopping power and response.

Longevity and Durability

Investing in quality suspension parts ensures longer-lasting components, reducing the need for frequent replacements and maintenance.

- Cost Savings : Fewer replacements and repairs.

- Reliability : Consistent performance over time.

Common Signs of Worn Suspension Parts

Uneven Tire Wear

Uneven tire wear is a common sign of worn suspension parts, indicating issues with alignment or component failure.

- Causes : Misaligned wheels, worn control arms or ball joints.

- Solutions : Regular inspections, timely replacements.

Excessive Bouncing

Excessive bouncing after hitting a bump suggests worn shock absorbers or springs, affecting ride comfort and stability.

- Causes : Worn shock absorbers, damaged springs.

- Solutions : Replace worn components, regular maintenance.

Steering Drift

Steering drift occurs when the vehicle pulls to one side, indicating issues with alignment or worn suspension parts.

- Causes : Misaligned wheels, worn control arms or ball joints.

- Solutions : Professional alignment, replace worn parts.

Maintaining Your Car’s Suspension System

Regular Inspections

Regular inspections are crucial for identifying and addressing issues with suspension components before they lead to significant problems.

- Frequency : At least twice a year or as recommended by the manufacturer.

- Focus Areas : Check for wear and tear, alignment issues, and fluid leaks.

Timely Replacements

Timely replacement of worn suspension parts ensures optimal performance and safety, preventing further damage to other components.

- Indicators : Uneven tire wear, excessive bouncing, steering drift.

- Benefits : Improved ride comfort, enhanced safety.

Professional Alignments

Professional alignments ensure proper wheel alignment, reducing tire wear and improving handling and fuel efficiency. Car interior components The inside parts of a car that you can see and touch like seats steering wheel dashboard and controls are called Vehicle coolant circulation moves liquid through the engine to keep it from getting too hot The coolant absorbs heat and carries it away to help the engine run smoothly

Vehicle component expenses The money spent on parts that make up a car or truck like tires wheels brakes and engines These costs can add up when fixing or replacing vehicle components Streamline parts inventory helps keep track of all the pieces needed to make things It makes sure you have enough parts and don’t run out when building or fixing stuff

Automotive tax percentage Vehicle maintenance essentials Regular oil changes and tire rotations keep your car running smoothly and safely for a long time Spare parts sourcing is finding and getting replacement pieces for machines or equipment when they break or wear out

Vehicle direction control helps drivers steer their cars trucks and other vehicles where they want to go It allows vehicles to turn left right or go straight on roads and highways Automotive mechanism distinctions Cars have different parts that work together to make them move and stop Some cars use gasoline engines while others use electric motors to power their wheels

Automotive camshaft mechanism The Brake system differences Cars can have different types of brakes like disc brakes or drum brakes which work in unique ways to slow down or stop the vehicle

- Frequency : Annually or after replacing suspension components.

- Benefits : Even tire wear, better handling, improved fuel efficiency.

Frequently Asked Questions (FAQs)

What are the main parts of a car suspension?

The main parts of a car suspension include springs, shock absorbers, anti-roll bars, ball joints, and control arms. These components work together to absorb shocks, maintain stability, and ensure proper wheel alignment.

How often should car suspension parts be replaced?

Car suspension parts should be replaced based on the manufacturer’s recommendations or when signs of wear and tear are evident. Regular inspections can help identify when components need replacement to maintain optimal performance and safety.

Can I replace suspension parts myself?

Replacing suspension parts yourself is possible if you have the necessary tools and mechanical knowledge. However, for complex components or if you’re unsure, it’s best to seek professional assistance to ensure proper installation and safety.

What causes car suspension parts to wear out?

Car suspension parts wear out due to factors such as regular use, harsh driving conditions, and lack of maintenance. Over time, components like shock absorbers, springs, and ball joints can deteriorate, affecting ride comfort and vehicle stability.

How much does it cost to replace car suspension parts?

The cost to replace car suspension parts varies depending on the specific components and vehicle type. On average, replacing a single suspension part can range from 00 to ,000, including labor costs. Regular maintenance can help reduce overall expenses by preventing extensive damage.

Statistics

According to the National Highway Traffic Safety Administration (NHTSA), faulty suspension components contribute to approximately 2% of all vehicle crashes in the United States. (Source: NHTSA )

A study by the Society of Automotive Engineers (SAE) found that properly maintained suspension systems can improve fuel efficiency by up to 3.5%. (Source: SAE )

The global automotive suspension parts market is projected to reach 3.9 billion by 2025, growing at a CAGR of 4.2% from 2020 to 2025. (Source: Markets and Markets )